| product | stainless steel round bar | |||||||

| title | Factory Price 201 304 321 904L 316L Stainless Steel Bar | |||||||

| Material | 301, 304, 304L, 309S, 321, 316, 316L, 317, 317L, 310S, 201,202,321, 329, 347, 347H 201, 202, 410, 420, 430, S20100, S20200, S30100, S30400, S30403, S30908, S31008, S31600, S31635, etc.. | |||||||

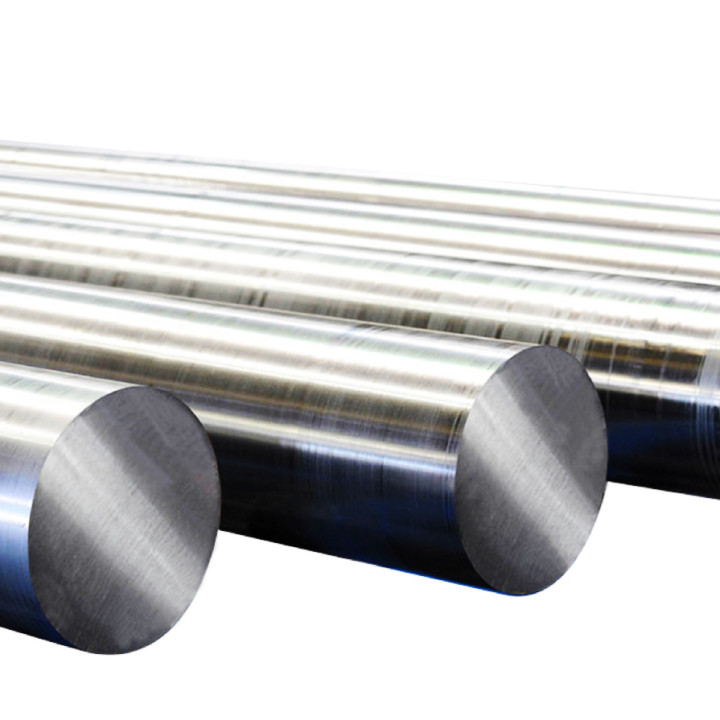

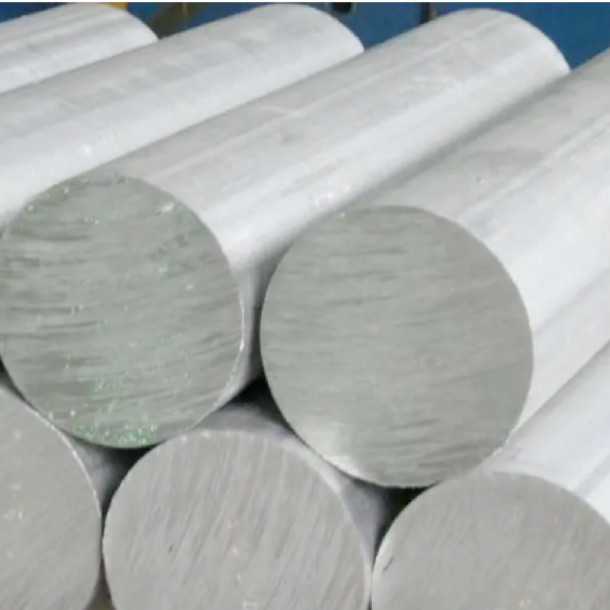

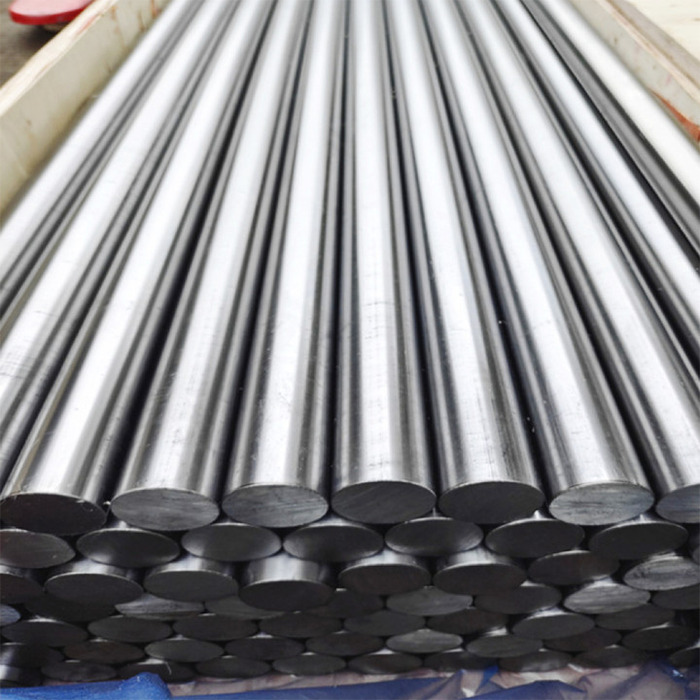

| Specifications | Round bar | Diámetro:0.1~500mm | ||||||

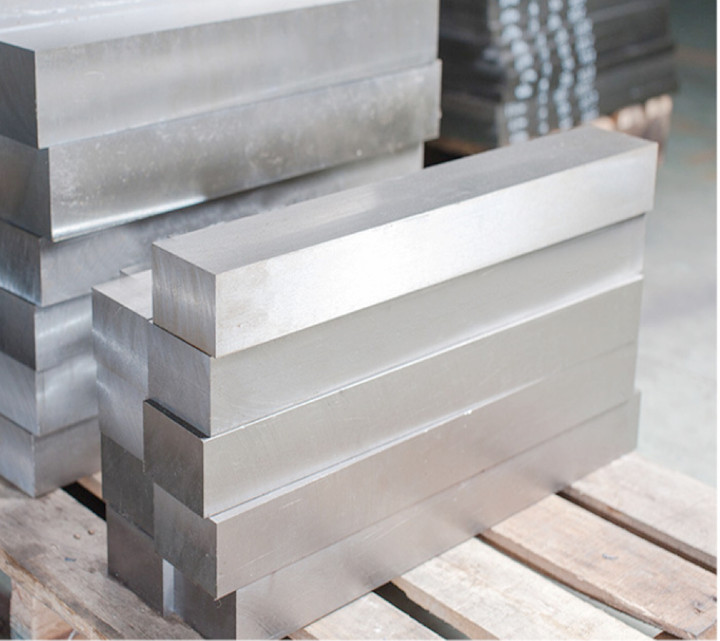

| Square bar | Tamaño: 1mm*1mm~800mm*800mm | |||||||

| Hexagonal bar | Tamaño: 2mm~100mm | |||||||

| Longitud | 2metro, 5.8metro, 6metro, o según sea necesario. | |||||||

| Surface | Black, peeled, polishing, bright, sand blast, hair line, etc.. | |||||||

| Standard | ASTM A479,ASTM A276,ASTM A484, ASTM A582, | |||||||

| ASME SA276, ASME SA484, GB/T1220, GB4226, etc.. | ||||||||

| MOQ | 1 ton , We can accept sample order. | |||||||

| Shipment Time | Within 7-15 workdays after receiving deposit or L/C | |||||||

| Export Packing | Standard seaworthy export packing or according to the customers’ request | |||||||

| Capacity | 25000 Ton/Tons per Month | |||||||

| Treatment/Technique | Hot rolled, cold drawn, Annealed, Grinding | |||||||

| Surface | Satin,400#, 600~1000# mirrorx, HL brushed,Brushed Mirror(two kinds of finishing for one pipe) | |||||||

| Standard | ASTM A276, A484, A479, A580, A582, JIS G4303, JIS G4311,DIN 1654-5,DIN 17440,GB/T 1220 | |||||||

| Technology | Bright, Polished, Turn smooth(Peeled),Brush, Mill, Pickled etc | |||||||

| Applications | Decorative /industrial/building material | |||||||

| Trade Terms | EXW, FOB, CFR, CIF | |||||||

| Delivery time | Shipped in 7-15 days after payment | |||||||

| Paquete | Standard sea-worthy package or as required | |||||||

| Container size | 20pies GP: 5.8metro(longitud) x 2.13m(width) x 2.18m(high) about 24-26CBM | |||||||

| 40pies GP: 11.8metro(longitud) x 2.13m(width) x 2.18m(high) about 54CBM 40ft HG: 11.8metro(longitud) x 2.13m(width) x 2.72m(high) about 68CBM | ||||||||

| Calificación | Compositionnominal wt% | Elongation % | Hardness |

| 301 Annealed 1/4H 1/2H FH | do .15, Minnesota 2.0, PAG .045, S 0.3, Y .75, Cr 16-18, Ni 6-8, N .1 | 40 | 95 Rb |

| 302 | do 0.15, Minnesota 2.0, PAG .045, S .03, Y .75 Cr 17-19, Ni 8-10, N .1 | 40 | 92 Rb |

| 303 | do 0.15, Minnesota 2.0, PAG .045, S .03, Y .75 Cr 17-19, Ni 8-10, N .1 | 30-50 | 92 Rb |

| 304 | do .08, Minnesota 2.0, PAG .045, S .03, Y .75 Cr 18-20, Ni 8-10.5, N .10 | 40 | 92 Rb |

| 304L | do .03, Minnesota 2, PAG .045, S .03, Y .75, Cr 18-20, Ni 8-12, N .1 | 40 | 92 Rb |

| 305 | do .12, Minnesota 2.0, PAG .045, S .03, Y .75, Cr 17-19, Ni 10.5-13, | 40 | 88 Rb |

| 309/309S | Type 309 – do .2, Minnesota 2.0, PAG .045, S.03, Y .75 Cr 22-24, Ni 12-15, Fe bal Type 309S – do .08, Minnesota 2.0, PAG .045, S .03, Y. 75, Cr 22-24, Ni 12-15, Fe Bal | 49/ 44.6 | – |

| 310L | Minnesota 1.10, Cr 24.5, Ni 20.5 (nominal) | 40 | 95 Rb |

| 310 310S | 310: do .25, Minnesota 2, PAG 0.045, S 0.03, Y 1.5, Cr 24-26, Ni 19-22, Fe balance 310S: do 0.08, Minnesota 2, PAG 0.045, S 0.30, Y 1.5, Cr 24-26, Ni 19-22, Fe balance | 45/42/6 | – |

| 316 | do .08, Minnesota 2.0, Y .75, Cr 16-18, Ni 10-14, Mo 2-3, PAG .045, S .03, N .1, Fe Bal | 40 | 95 Rb |

| 316L | do .03, Minnesota 2.0, Y .75, Cr 16-18, Ni 10-14, Mo 2-3, PAG .045, S .03, N 0.1, Fe Bal | 54 | 95 Rb |

| 316Ti | do .08, Minnesota 2.0, Y .75, Cr 16-18, Ni 10-14, Mo 2-3, PAG 0.045, S 0.03, N 0.1, Ti 0.15-0.70, balance Fe | 248 | 76 Rb |

| 317 | Type 317 – do .08, Minnesota 2.0, Y .75, Cr 18-20, Ni 11-15, Mo 3-4, PAG .045, S .03, N .10, Fe Bal | 35 | 95 Rb |

| 321 | do .09, Minnesota 2.0, PAG .045, S .03, Y .75, Cr 17-18, Ni 9-12, Ti .7, N .1 Fe Bal | 40 | 95 Rb |

| 334 | do 0.03, Minnesota 1.0, PAG .02, S .015, Y .75, Cr 19-19.5 Ni 19-20, Ti .4, Al .4, Cu .2 Fe Bal | 40 | 82 Rb |

| 347 | do .08, Minnesota 2.0, PAG .045, S .03, Y .75, Cr 17-19, Ni 9-13, Cb+Ta 1.0, Fe Bal | 40 | 95 Rb |

| 348 | do .08, Minnesota 2.0, PAG .045, S .03, Si.75, Cr 17-19, ni 9-13, Cb+Ta 1.0, Ta .10, Co .2, Fe Bal | 40 | 92 Rb |

| 410 | do .15, Minnesota 1.0, Y 1.0, Cr 11.5-13.5, Ni 0.5, S .03, Ph .04 | 34 | 38-45 Rc |

| 416 | do 0.15, Minnesota 1.25, Y 1.0, Cr 12-14, PAG 0.06, S 0.15, Mo 0.60, Fe Balance | 15-30 | |

| 420 | do .15-.40, Minnesota 1.0, Y 1.0, Cr 12-14, Ni 0.5, S .03, Ph .04 | 15-30 | 53-57 Rc |

| 440A | do .60-.75, Minnesota 1.0, Y 1.0, Cr 16-18, Mo .75, Ni .50, S.03, Ph .04 | 20 | 57-60 Rc |

| 440do | Cr 16.5, do 1.0, Y 1.0 | – | 58 Rc |

| 13-8 Mo | Cr 13, Ni 8, Mo 2, Al, low C, balance Fe | 18 | 33 Rc |

| 15-5PH | Cr 15, Ni 5, Cu 3, Cb, balance Fe | 10 | 33 Rc |

| 15-7Mo | Cr 15, Ni 7, Mo 2, AL 1, balance Fe | 30 | 88 Rb |

| 17-4PH | Cr 17, Ni 4,Cu 3, Cb, balance Fe | 8 | 33 Rc |

| Chemical Properties of Frequently-used Stainless Steel Material Grade | |||||||||||

| UNS | ASTM | EN | JIS | C% | Mn% | P% | S% | Si% | Cr% | Ni% | Mo% |

| S20100 | 201 | 1.4372 | SUS201 | ≤0.15 | 5.5-7.5 | ≤0.06 | ≤0.03 | ≤1.00 | 16.0-18.0 | 3.5-5.5 | – |

| S20200 | 202 | 1.4373 | SUS202 | ≤0.15 | 7.5-10.0 | ≤0.06 | ≤0.03 | ≤1.00 | 17.0-19.0 | 4.0-6.0 | – |

| S30100 | 301 | 1.4319 | SUS301 | ≤0.15 | ≤2.00 | ≤0,045 | ≤0.03 | ≤1.00 | 16.0-18.0 | 6.0-8.0 | – |

| S30400 | 304 | 1.4301 | SUS304 | ≤0.08 | ≤2.00 | ≤0,045 | ≤0.03 | ≤0.75 | 18.0-20.0 | 8.0-10.5 | – |

| S30403 | 304L | 1.4306 | SUS304L | ≤0.03 | ≤2.00 | ≤0,045 | ≤0.03 | ≤0.75 | 18.0-20.0 | 8.0-12.0 | – |

| S30908 | 309S | 1.4833 | SUS309S | ≤0.08 | ≤2.00 | ≤0,045 | ≤0.03 | ≤0.75 | 22.0-24.0 | 12.0-15.0 | – |

| S31008 | 310S | 1.4845 | SUS310S | ≤0.08 | ≤2.00 | ≤0,045 | ≤0.03 | ≤1.50 | 24.0-26.0 | 19.0-22.0 | – |

| S31600 | 316 | 1.4401 | SUS316 | ≤0.08 | ≤2.00 | ≤0,045 | ≤0.03 | ≤0.75 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

| S31603 | 316L | 1.4404 | SUS316L | ≤0.03 | ≤2.00 | ≤0,045 | ≤0.03 | ≤0.75 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

| S31703 | 317L | 1.4438 | SUS317L | ≤0.03 | ≤2.00 | ≤0,045 | ≤0.03 | ≤0.75 | 18.0-20.0 | 11.0-15.0 | 3.0-4.0 |

| S32100 | 321 | 1.4541 | SUS321 | ≤0.08 | ≤2.00 | ≤0,045 | ≤0.03 | ≤0.75 | 17.0-19.0 | 9.0-12.0 | – |

| S34700 | 347 | 1.455 | SUS347 | ≤0.08 | ≤2.00 | ≤0,045 | ≤0.03 | ≤0.75 | 17.0-19.0 | 9.0-13.0 | – |

| S40500 | 405 | 1.4002 | SUS405 | ≤0.08 | ≤1.00 | ≤0.04 | ≤0.03 | ≤1.00 | 11.5-14.5 | ≤0.60 | – |

| S40900 | 409 | 1.4512 | SUS409 | ≤0.08 | ≤1.00 | ≤0,045 | ≤0.03 | ≤1.00 | 10.5-11.75 | ≤0.50 | – |

| S43000 | 430 | 1.4016 | SUS430 | ≤0.12 | ≤1.00 | ≤0.040 | ≤0.03 | ≤0.75 | 16.0-18.0 | ≤0.60 | – |

| S43400 | 434 | 1.4113 | SUS434 | ≤0.12 | ≤1.00 | ≤0.040 | ≤0.03 | ≤1.00 | 16.0-18.0 | – | – |

| S44400 | 444 | 1.4521 | SUS444L | ≤0.025 | ≤1.00 | ≤0,045 | ≤0.03 | ≤1.00 | 17.5-19.5 | ≤1.00 | – |

| S40300 | 403 | – | SUS403 | ≤0.15 | 5.5-7.5 | ≤0.04 | ≤0.03 | ≤0.50 | 11.5-13.0 | ≤0.60 | – |

| S410000 | 410 | 1.40006 | SUS410 | ≤0.15 | ≤1.00 | ≤0.035 | ≤0.03 | ≤1.00 | 11.5-13.5 | ≤0.60 | ≤1.00 |

| S42000 | 420 | 1.4021 | SUS420J1 | 0.16~0.25 | ≤1.00 | ≤0.04 | ≤0.03 | ≤1.00 | 12.0-14.0 | ≤0.75 | ≤1.00 |

| S440A | 440A | 1.4028 | SUS440A | 0.60~0.75 | ≤1.00 | ≤0.04 | ≤0.03 | ≤1.00 | 16.0-18.0 | – | ≤0.75 |

| S32750 | SAD2507 | 1.441 | ≤0.03 | ≤1.2 | ≤0.035 | ≤0.02 | ≤0.80 | 24.0-26.0 | 6.0-8.0 | 3.0-5.0 | |

| S31803 | SAF2205 | 1.4462 | ≤0.03 | ≤2.0 | ≤0.03 | ≤0.02 | ≤1.00 | 21.0-23.0 | 4.0-6.5 | 2.5-3.5 | |

| N08904 | 904L | 1.4539 | ≤0.0.3 | ≤2.0 | ≤0.035 | ≤0.03 | ≤1.00 | 18.0-20.0 | 23.0-25.0 | 3.0-4.0 | |