How are the steel profiles that are used in construction and manufacturing made?

The coil of steel is moved from the warehouse into the slitting station. Here they take the coil of steel sheet and cut it into sections, with the width corresponding directly to the dimensions of the end product.

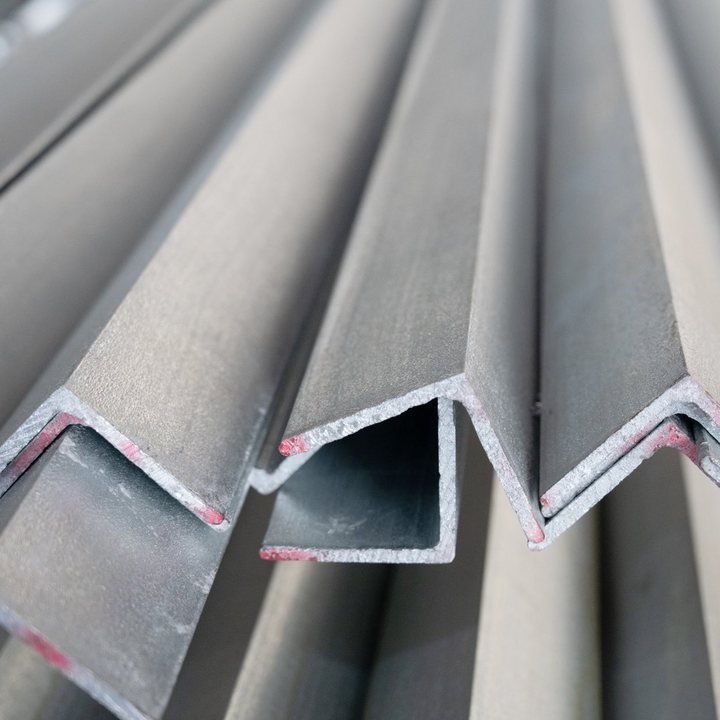

This now correctly sized material is then moved to the start of the actual manufacturing station. They start to roll this material into the steel profile shape. Whether that’s square, rectangular or into other shapes such as angles or tubes.

In this case, the actual rolling element of the machine is changed out dependent on the requirements. It’s then preset for the next product to be produced.

Once the steel profile is at the desired size and shape, the steel is cut to the required length (normally 6000mm – though we have suppliers that can do custom lengths). It is then cooled by running water through the profile.

The steel profile is then ready to be packaged, in another automated machine before being moved out into the warehouse. From there it’s shipped out to us at Zystal and then onwards to our customers.

Overall, it is a very interesting process and is fascinating to see first-hand.