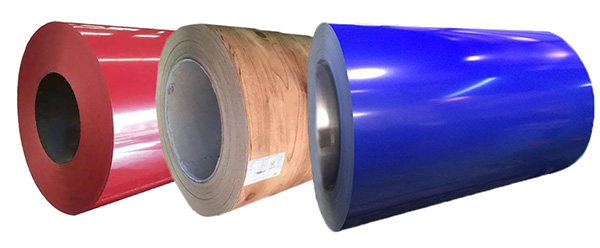

The full form of PPGI is pre-painted galvanized iron. It is a kind of color coated steel or pre-painted steel, which is an extension of GI. As the name implies, it uses zinc-coated steel as substrate, and then it is cleaned, pre-treated, and applied with layers of coatings to make it more beautiful and durable to use.

As the picture shows, PPGI steel contains base metal, zinc coating, pre-treatment (chemical conversion coating), primer coating, and top/back coating.

PPGI uses galvanized steel as base metal, which includes hot-dip galvanized and electro galvanized steel. The former is more corrosion-resistant and durable since the zinc layer can reach up to 275 g/㎡. While the zinc layer of the electro-galvanized sheet is thin, usually within 30 g/㎡. Therefore, hot-dip PPGI steel is more suitable for making roofing or wall panels for outdoor uses. While considering the smooth appearance of electro-galvanized PPGI steel, it is an ideal option for interior decoration, home appliances, furniture, etc. At Wanzhi Steel, we mainly use hot-dip galvanized sheets as the base metal.